Solution for pre-embedded foundation of fixed column jib crane

Maximum load: 5 tons Maximum arm length: 10 meters

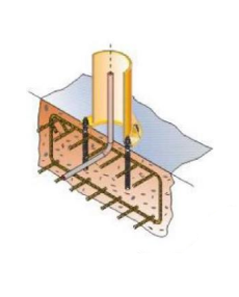

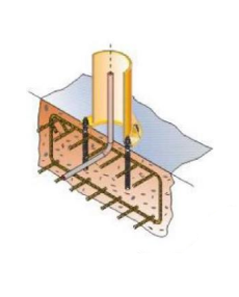

A Pre-embedded concrete parts Currently, the most commonly used method for fixed-column jib cranes is pre-embedded concrete. First, embed the pre-embedded bolts in the concrete. After the concrete solidification period, the jib crane is connected with the pre-embedded bolts. After completion, the verticality of the jib crane is corrected.

B Ideal pre-embedded foundation By pre-embedding professional positioning devices, the workload of adjusting the verticality of the jib crane column has been reduced.

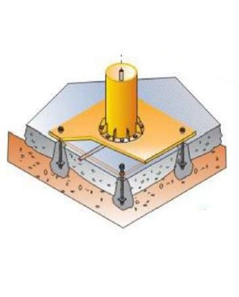

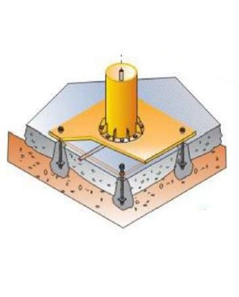

C Large base plate installation, concrete floor has been poured Now install the square large base plate on the ground with chemical bolts, adjust the horizontality of the large base plate, and tighten the large base plate; then connect the jib crane column with the bolt holes on the large base plate. This method is suitable for small-tonnage jib cranes with good ground conditions.

D Large base plate installation, concrete floor Now install the square large base plate on the concrete ceiling through long screws, adjust the level of the large base plate, and tighten the bolts at both ends; finally connect the jib crane column with the bolt holes on the large base plate. This method is suitable for small-tonnage jib cranes with very good ceiling conditions.

E Positioning pin plate concrete floor/concrete ceiling When the jib crane has special positioning requirements, we use adjustable pins installation, especially with dynamic loads, installed countersunk round pin plates, using German Fischer pins. We will provide a complete set of solutions and accessories.