Form Factor |

Rated load kg |

Standard lifting height m |

Lifting speed m/min |

Motor Power kW |

Lower hook Number of chains | IP Rating |

net weight kg |

A | 125 | 3 | 8.1 | 0.16 | 1 | 54 | 32 |

AA | 125 | 3 | 15.2 | 0.31 | 1 | 54 | 33 |

B | 250 | 3 | 4.1 | 0.16 | 1 | 54 | 32 |

C | 250 | 3 | 8.1 | 0.31 | 1 | 54 | 33 |

E | 500 | 3 | 2.0 | 0.16 | 2 | 54 | 31 |

F | 500 | 3 | 4.1 | 0.31 | 1 | 54 | 33 |

| 500 | 3 | 8.1 | 0.62 | 1 | 54 | 55 |

JJ | 500 | 3 | 16.3 | 1.24 | 1 | 54 | 58 |

H | 1000 | 3 | 2.0 | 0.31 | 2 | 54 | 35 |

L | 1000 | 3 | 4.1 | 0.62 | 1 | 54 | 54 |

LL | 1000 | 3 | 8.1 | 1.24 | 1 | 54 | 58 |

R | 2000 | 3 | 2.0 | 0.62 | 2 | 54 | 64 |

RR | 2000 | 3 | 4.1 | 1.24 | 2 | 54 | 68 |

RT | 3000 | 3 | 1.4 | 0.62 | 3 | 54 | 73 |

RRT | 3000 | 3 | 2.7 | 1.24 | 3 | 54 | 78 |

Lodestar(Dual speed)

Form Factor | Rated load kg | Standard lifting height m | Lifting speed m/min | Motor Power kW | Lower hook Number of chains | IP Rating | net weight kg |

A-2 | 125 | 3 | 2.7/8.1 | 0.16 | 1 | 54 | 35 |

AA-2 | 125 | 3 | 5.1/15.2 | 0.31 | 1 | 54 | 35 |

B-2 | 250 | 3 | 1.4/4.1 | 0.16 | 1 | 54 | 35 |

C-2 | 250 | 3 | 2.7/8.1 | 0.31 | 1 | 54 | 35 |

E-2 | 500 | 3 | 0.7/2.0 | 0.16 | 2 | 54 | 34 |

F-2 | 500 | 3 | 1.4/4.1 | 0.31 | 1 | 54 | 35 |

J-2 | 500 | 3 | 2.7/8.1 | 0.62 | 1 | 54 | 60 |

JJ-2 | 500 | 3 | 5.4/16.3 | 1.24 | 1 | 54 | 61 |

H-2 | 1000 | 3 | 0.7/2.0 | 0.31 | 2 | 54 | 38 |

L-2 | 1000 | 3 | 1.4/4.1 | 0.62 | 1 | 54 | 59 |

LL-2 | 1000 | 3 | 2.7/8.1 | 1.24 | 1 | 54 | 58 |

R-2 | 2000 | 3 | 0.7/2.0 | 0.62 | 2 | 54 | 61 |

RR-2 | 2000 | 3 | 1.4/4.1 | 1.24 | 2 | 54 | 70 |

RT-2 | 3000 | 3 | 0.5/1.4 | 0.62 | 3 | 54 | 72 |

RRT-2 | 3000 | 3 | 0.9/2.7 | 1.24 | 3 | 54 | 82 |

** The above data is based on 380V-3PH-50Hz

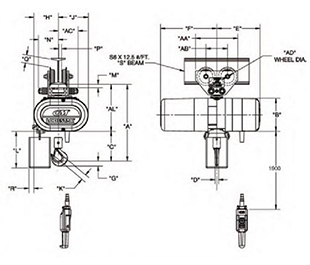

Series 635 Low Headroom Trolley

Rated load kg | Corresponding appearance Specification | Standard I-beam mm | Trolley tire tread diameter mm | Minimum turning radius mm |

125-1000 | AtoLL-2 | 102-381 | 79.4 | 610 |

2000 | RtoRR-2 | 152-457 | 120.6 | 610 |

3000 | RTtoRRT-2 | 203-381 | 101.6 | 762 |

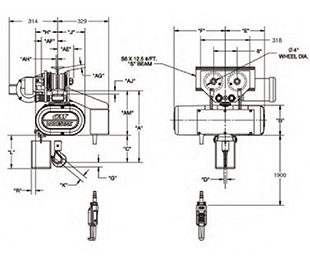

Series 635 Integrated Electric Cart

Rated load kg | Corresponding appearance Specification | Standard I-beam Depth adjustment mm | Trolley tire tread diameter mm | Minimum turning radius mm |

125-1000 | AtoLL-2 | 102-381 | 79.4 | 610 |

2000 | RtoRR-2 | 152-457 | 120.6 | 610 |

3000 | RTtoRRT-2 | 203-381 | 101.6 | 762 |